Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Insights Center

- Haskel Innovation Results in Higher Pressures, Increased Oxygen Content & Cost Savings for High-Pressure Systems Customer

Haskel Innovation Results in Higher Pressures, Increased Oxygen Content & Cost Savings for High-Pressure Systems Customer

Dave Gordon, Haskel’s west coast Regional Sales Manager, recently received a call from a company using a competitive gas booster system who was looking for a quote on a replacement for their R&D lab. True to Haskel's commitment to innovation, Dave began not by seeking to replicate someone else's design but rather to build something to fit this customer's unique application.

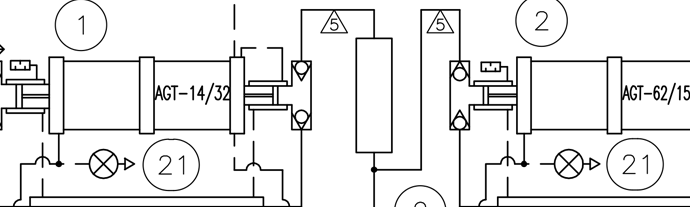

Dave and his team reviewed all of the other systems they had built and determined that although they could use a standard booster and standard frame, this latest system itself would be one of a kind. In designing the 83412 system, Haskel was able to reduce the number of boosters the customer needed, resulting in lower maintenance costs and a significant reduction in compressed air consumption.

Photo: Partial engineering drawing of custom system

In addition, re-engineering the solution for this customer resulted in the ability to achieve higher pressures than before, as high as 14,000 psi. Typically at pressures this high, oxygen would not be used due to its combustibility. But Haskel, using its special oxygen cleaning techniques, designed a system that could safely accommodate up to 20 percent oxygen content.

Haskel's customer was thrilled with the results—a system that will allow their R&D team to continue seeking to achieve peak product performance using high-pressure gasses.

Always looking for a better solution is the Haskel way. To discuss how Haskel can create a custom system to fit your needs, contact us today.